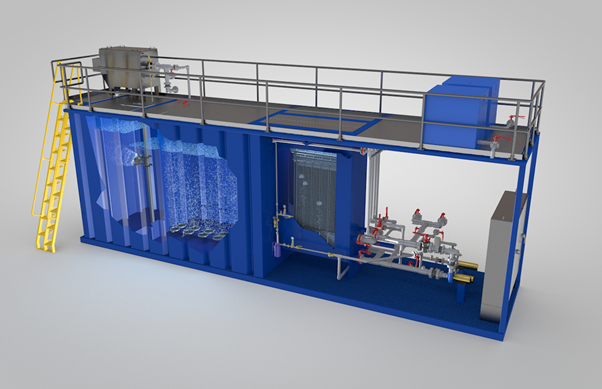

It is now widely used for municipal and industrial wastewater treatment. Membrane Bioreactor is an innovative wastewater treatment method. As the name suggests, it combines two technologies, membrane filtration and the biological treatment.

• A reduced footprint, usually( 30-50% smaller than an equivalent conventional active sludge facility with secondary clarifiers and media tertiary filtration).

• The process also produces exceptional effluent quality capable of meeting the most stringent water quality requirements.

• A modular schematic that allows for ease of expansion and configuration flexibility, a robust and reliable operation and reduced downstream disinfection requirements.

Membrane bioreactor wastewater treatment combines the conventional biological process, i.e., activated sludge, with the membrane filtration technology. You could say that the membrane bioreactor working principle is all about the ingenious combo of membrane technology and biological treatment.

• In MBR technology system, the semi-permeable membranes, which are two- dimensional materials, (micro and ultrafiltration) are submerged in aerated biological reactors.

• It also aids in the elimination of sedimentation and filtration processes that are commonly used for wastewater treatment.

• Since the need for sedimentation is removed, the biological process can be operated more effectively.

• In MBR technology system, the semi-permeable membranes, which are two- dimensional materials, (micro and ultrafiltration) are submerged in aerated biological reactors.

• A fine screening or pre-treatment is done before the waste enters membrane tank. It helps to protect the membrane and extend its life by minimizing the accumulation of solid wastes.